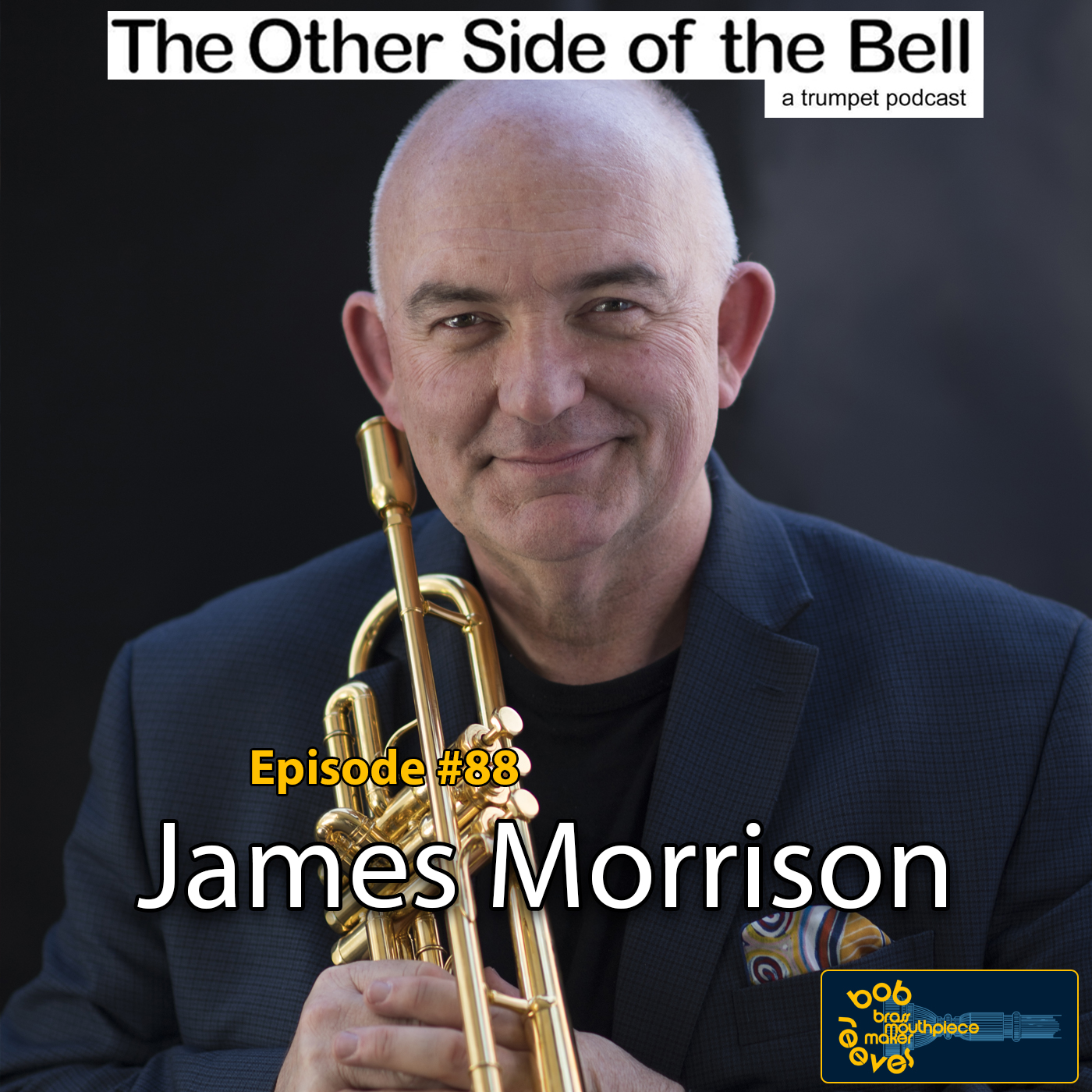

James Morrison is, by anybody’s standard, a virtuoso in the true sense of the word. Besides the trumpet, this multi-instrumentalist also plays piano, all the brass, saxophones, and double bass.

James Morrison is, by anybody’s standard, a virtuoso in the true sense of the word. Besides the trumpet, this multi-instrumentalist also plays piano, all the brass, saxophones, and double bass.

At the age of six he started on piano, at seven he took up brass, at nine he formed his first band and at thirteen he was playing professionally in nightclubs. His international career developed just as quickly with a debut in the USA at the Monterey Jazz Festival at age sixteen.

Following this were performances at the world’s major jazz festivals, including Montreux, North Sea, Nice and the Hollywood Bowl, playing with many of the legends of jazz – Dizzy Gillespie, Herbie Hancock, Dave Brubeck, Chick Corea, George Benson, Ray Charles, B.B. King, Quincy Jones, Ray Brown and Wynton Marsalis to name a few. James also frequents the world’s most famous jazz clubs – Birdland, The Blue Note and Village Vanguard in New York, New Morning in Paris, The Tokyo Blue Note and Ronnie Scott’s in London.

Now 58, James Morrison’s career has included much more than just jazz…

He has recorded with The London Symphony Orchestra, rock legends INXS and the European Brass Ensemble, performed at the Royal Albert Hall for the BBC Proms, written the opening fanfare for the Olympic Games, played Royal Command performances for Her Majesty Queen Elizabeth II and for US Presidents Bush and Clinton. He has played classical trumpet at the Kremlin, was TV presenter on Top Gear Australia and on International Jazz Day 2016, James was a guest of President Obama at the White House.

James has been appointed a member of The Order of Australia, he is a Doctor of the University at Queensland Conservatorium of Music and has received a Doctor of Music from the Edith Cowan University Western Australia and the University of Adelaide. He is an Adjunct Professor at the University of South Australia and Vice-Chancellor’s Professorial Fellow. In 2015 James founded his own academy of music in Mount Gambier, South Australia. The James Morrison Academy of Music @ UniSA is an innovative school dedicated to teaching jazz and offering both a Bachelor Degree and post graduate programs. This exciting initiative involves educators from all over the world, transforming young musicians’ lives with inspiration and a love of jazz. In 2017, the JMA partnered with The Juilliard School in New York City to offer an exclusive Honours Program.

James has been appointed a member of The Order of Australia, he is a Doctor of the University at Queensland Conservatorium of Music and has received a Doctor of Music from the Edith Cowan University Western Australia and the University of Adelaide. He is an Adjunct Professor at the University of South Australia and Vice-Chancellor’s Professorial Fellow. In 2015 James founded his own academy of music in Mount Gambier, South Australia. The James Morrison Academy of Music @ UniSA is an innovative school dedicated to teaching jazz and offering both a Bachelor Degree and post graduate programs. This exciting initiative involves educators from all over the world, transforming young musicians’ lives with inspiration and a love of jazz. In 2017, the JMA partnered with The Juilliard School in New York City to offer an exclusive Honours Program.

James has also written and performed his own concerto with the Tonkünstler Orchestra at the Musikverein in Vienna and has appeared as a guest with the Berlin Philharmonic, the Czech National Symphony Orchestra at the Prague Proms and many more of the world’s major orchestras.

In 2018, James’s activities included a return performance to the legendary Bern Jazz Festival in Switzerland, The New Zealand International Jazz and Blues Festival, the Melbourne International Jazz Festival and a as special guest at UNESCO International Jazz Day at the Mariinsky Theatre in St Petersburg. James and his new quartet embarked on an Australian jazz club tour to promote their debut album “Midnight Till Dawn” as well as a tour to the United States and Europe (Austria, Ireland, Portugal and the UK). In London, James presented a 4-part documentary series “Top Brass” for the BBC. James also appeared in the 2018 seasons of the West Australian Symphony Orchestra and the Auckland Philharmonic Orchestra.

2017 highlights included a world premier of a jazz concerto written specially for James by Gordon Goodwin on International Jazz Day, a debut at the BBC Proms in London alongside Dianne Reeves, return performances at Jazz at Lincoln Center, Ronnie Scott’s and the Jazz Cruise, a debut at The Green Mill in Chicago, headline appearances at Melbourne International Jazz Festival, Canberra International Music Festival, Oslo Jazz Festival, Vail Jazz Festival Colorado and Grahamstown International Music Festival South Africa, an Australian tour with Grammy Award winning diva Patti Austin and featured appearances at the Sydney Opera House for Australia Day and the Australian Embassy in Washington DC for the Presidential Inauguration. 2017 recording releases included a recording of the Great American Songbook at Abbey Road Studios with the BBC Concert Orchestra. James also continues his education work with appearances in New Orleans at the Jazz Educator’s Network Conference and workshops at the Juilliard School, the Thelonious Monk Institute and University of North Texas’s One O’Clock Lab Band.

Highlights of 2016 included a recording at Abbey Road Studios with the BBC Concert Orchestra for international release, sold out performances at the Prague Proms, Berlin Philhamonie, Budapest Music Centre and the Lionel Hampton Club in Paris, two sell-out return performances at Ronnie Scott’s Jazz Club in London, two Australian tours, two European tours, a season with the Sydney Symphony Orchestra, a hugely successful solo tour all over the USA including the Miami Beach Jazz Festival, the Newport Beach Jazz Party, performances with John Clayton, Jeff Hamilton and the One O’Clock Lab Band and, of course, International Jazz Day at the White House with the President of the United States.

Highlights of 2016 included a recording at Abbey Road Studios with the BBC Concert Orchestra for international release, sold out performances at the Prague Proms, Berlin Philhamonie, Budapest Music Centre and the Lionel Hampton Club in Paris, two sell-out return performances at Ronnie Scott’s Jazz Club in London, two Australian tours, two European tours, a season with the Sydney Symphony Orchestra, a hugely successful solo tour all over the USA including the Miami Beach Jazz Festival, the Newport Beach Jazz Party, performances with John Clayton, Jeff Hamilton and the One O’Clock Lab Band and, of course, International Jazz Day at the White House with the President of the United States.

Other career highlights include performing with artists as diverse as Phil Collins, Chaka Khan and Sting.

He spends much time in education, doing master classes and workshops in many countries and presenting the James Morrison Jazz Scholarship at the world’s largest youth jazz festival Generations in Jazz.

When not writing film scores, composing or serving as patron of some of Australia’s major music institutions, James relaxes in some unconventional ways for a musician – flying his private plane or driving in a rally championship.

In a recording career spanning 3 decades, James has released a huge variety of albums from gospel to big band to electronic fusion. Nominated for eight ARIA Awards winning ARIA in 2010 and again in 2017. In 2013, James was inducted into the Australian Jazz Hall of Fame. In 2016, James’s disc “In Good Company” charted simultaneously in both the ARIA Jazz and Popular Album Charts, remaining at No 1 in the Jazz charts for over 20 weeks. James currently records for ABC Jazz/Universal and Fanfare Jazz and is an exclusive artist for Schagerl Instruments. He is also a proud Friend of the Brand for Mercedes Benz and Brand Ambassador for Oris Swiss Watches.

In 2012 James was appointed Artistic Director of the Queensland Music Festival, a state-wide music initiative whose vision is to “transform lives through unforgettable musical experiences.” As part of the festival, in 2013 James conducted the World’s Largest Orchestra, breaking a Guinness World Record with 7,224 musicians at Brisbane’s Suncorp Stadium. In 2014 James presented ‘A Tribute to Oscar Peterson’ at the Edinburgh Jazz Festival as part of the Commonwealth Games celebrations.

In 2019, James was the Co-Artistic Director (with Herbie Hancock) of International Jazz Day which was ‘live streamed’ from Melbourne, Australia to a world-wide audience of more than

With interests so broad and a career so filled with highlights it seems that James Morrison must have done just about everything he could want to do – but not so…

When asked, “What is there left to do?” James’ reply is typically “This is just the warm up!”

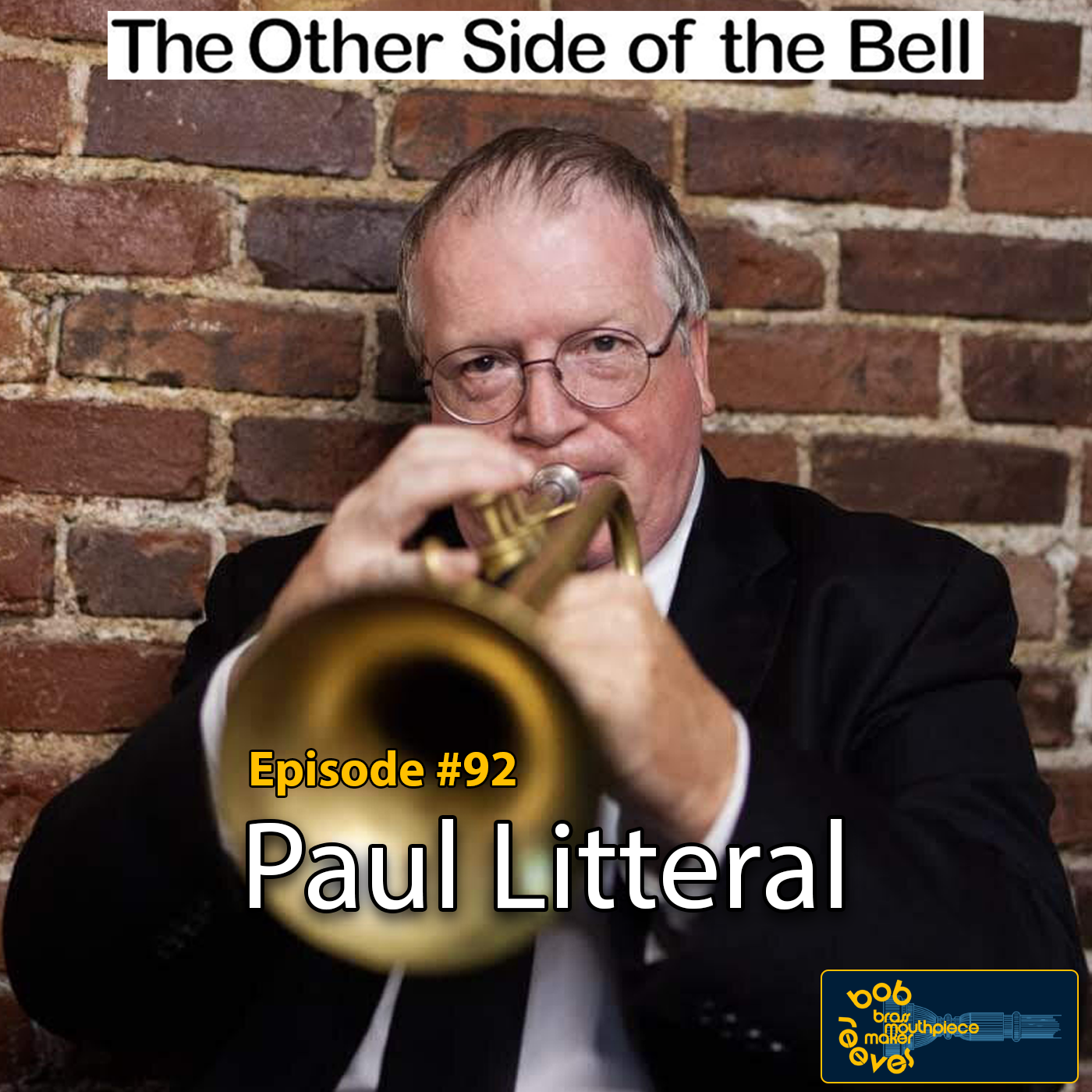

Paul Litteral was born and raised in Western Kentucky and by the fifth grade he knew that he was going to play the trumpet. After high school, he wanted to play in the Naval School of Music, so he auditioned, was accepted, and then enlisted in the Navy. After some time in Virginia, he was invited to join the band at the duty station in New York City and, when the Navy consolidated its bands at the War College in Rhode Island, he moved there. Having completed his four year tour of duty, Paul left the Navy and returned to New York.

Paul Litteral was born and raised in Western Kentucky and by the fifth grade he knew that he was going to play the trumpet. After high school, he wanted to play in the Naval School of Music, so he auditioned, was accepted, and then enlisted in the Navy. After some time in Virginia, he was invited to join the band at the duty station in New York City and, when the Navy consolidated its bands at the War College in Rhode Island, he moved there. Having completed his four year tour of duty, Paul left the Navy and returned to New York.

Currently, Paul is playing trumpet and flugelhorn with Angela O’Neill and the Outrageous8. Angela founded the band in 2016 and Paul is one of the original members. He plays a Maxx II trumpet designed by Charles Colin and manufactured by Kanstul Company. When he wants a darker, lower tone, he switches over to flugelhorn, a perfect choice for ballads and medium tempo tunes. His flugelhorn is a Custom Z from Yamaha. Even though he toured much of the world while playing with the Uptown Horns, he still enjoys travel and particularly wants to spend time in Italy, Spain and Ireland. When taking a break from playing music and writing, he enjoys freshwater fishing, primarily as a catch and release fisherman. Asked about favorite foods, Paul’s tastes are eclectic—he likes Asian and Indian cuisine but also loves a great steak.

Currently, Paul is playing trumpet and flugelhorn with Angela O’Neill and the Outrageous8. Angela founded the band in 2016 and Paul is one of the original members. He plays a Maxx II trumpet designed by Charles Colin and manufactured by Kanstul Company. When he wants a darker, lower tone, he switches over to flugelhorn, a perfect choice for ballads and medium tempo tunes. His flugelhorn is a Custom Z from Yamaha. Even though he toured much of the world while playing with the Uptown Horns, he still enjoys travel and particularly wants to spend time in Italy, Spain and Ireland. When taking a break from playing music and writing, he enjoys freshwater fishing, primarily as a catch and release fisherman. Asked about favorite foods, Paul’s tastes are eclectic—he likes Asian and Indian cuisine but also loves a great steak.

Born in Luxembourg, Philippe Schartz developed an early interest in the trumpet from listening to his father play in the village wind band. His passion was cultivated by his teachers who have included Dino Tomba, a great friend and mentor. He continued his studies at the Royal College of Music in London with the late David Mason, and then was invited to join the Special Student programme at the Eastman School of Music in Rochester, New York.

Born in Luxembourg, Philippe Schartz developed an early interest in the trumpet from listening to his father play in the village wind band. His passion was cultivated by his teachers who have included Dino Tomba, a great friend and mentor. He continued his studies at the Royal College of Music in London with the late David Mason, and then was invited to join the Special Student programme at the Eastman School of Music in Rochester, New York. An enthusiastic member of the teaching staff at the Royal Welsh College of Music and Drama and Cardiff University, Philippe has given master-classes/recitals

An enthusiastic member of the teaching staff at the Royal Welsh College of Music and Drama and Cardiff University, Philippe has given master-classes/recitals

Inspired by the great valve trombonist BOB BROOKMEYER, Barry Mosley is keeping the legacy of playing jazz valve trombone. The first important jazz valve trombonist were JUAN TIZOL and BRAD GOWANS in the 1930s and 1940s, setting the stage for others. The valve trombone has a unique place in jazz history.

Inspired by the great valve trombonist BOB BROOKMEYER, Barry Mosley is keeping the legacy of playing jazz valve trombone. The first important jazz valve trombonist were JUAN TIZOL and BRAD GOWANS in the 1930s and 1940s, setting the stage for others. The valve trombone has a unique place in jazz history.

RIM

RIM Dan Rosenboom is an internationally recognized trumpet player, composer, and producer. He is known as a prolific member of the Los Angeles creative music scene, having released more than 25 albums of original music as a solo artist and bandleader and has supported over 60 artists across nearly 90 releases on his label, Orenda Records. Rosenboom frequently performs in Hollywood Studios for major film and television soundtracks, highlighted by the latest Star Wars trilogy, with such notable composers as John Williams, Danny Elfman, James Newton Howard, Alan Silvestri, and Alexandre Desplat. He has also performed often with such elite ensembles as the LA Philharmonic, the LA Chamber Orchestra, and the LA Opera. His own music eschews genre distinctions and draws from such disparate influences as jazz and Black American Music, metal and experimental rock, contemporary classical music, folk music from around the globe, and a broad range of progressive music from the avant-garde. He studied at the Eastman School of Music, CalArts, and UCLA, where he earned advanced degrees in music. The Los Angeles Times has called Dan Rosenboom “a musician dedicated to exploration and expression, regardless of anyone’s imagined boundaries,” and “a phenomenon.”

Dan Rosenboom is an internationally recognized trumpet player, composer, and producer. He is known as a prolific member of the Los Angeles creative music scene, having released more than 25 albums of original music as a solo artist and bandleader and has supported over 60 artists across nearly 90 releases on his label, Orenda Records. Rosenboom frequently performs in Hollywood Studios for major film and television soundtracks, highlighted by the latest Star Wars trilogy, with such notable composers as John Williams, Danny Elfman, James Newton Howard, Alan Silvestri, and Alexandre Desplat. He has also performed often with such elite ensembles as the LA Philharmonic, the LA Chamber Orchestra, and the LA Opera. His own music eschews genre distinctions and draws from such disparate influences as jazz and Black American Music, metal and experimental rock, contemporary classical music, folk music from around the globe, and a broad range of progressive music from the avant-garde. He studied at the Eastman School of Music, CalArts, and UCLA, where he earned advanced degrees in music. The Los Angeles Times has called Dan Rosenboom “a musician dedicated to exploration and expression, regardless of anyone’s imagined boundaries,” and “a phenomenon.”

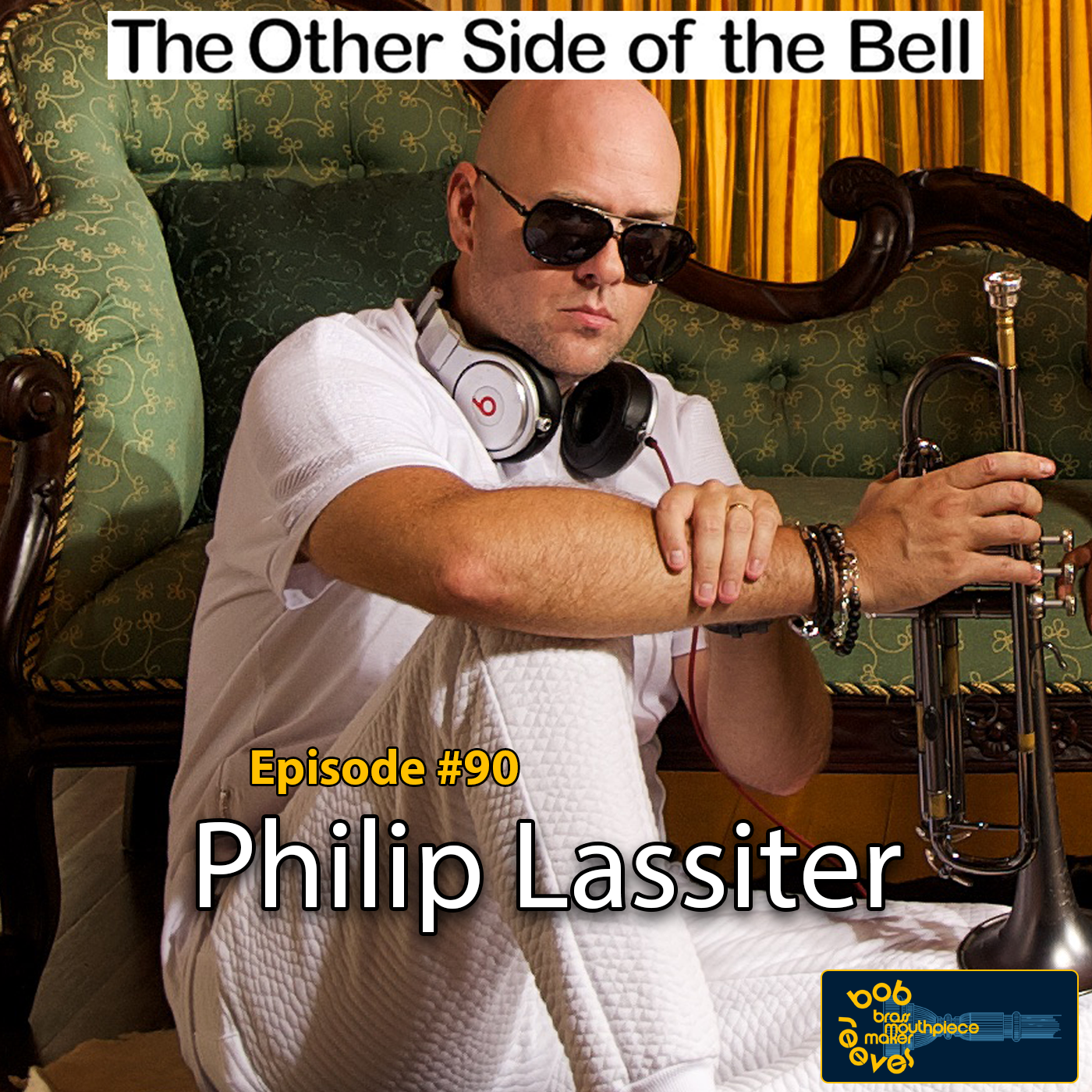

Philip Lassiter is an 11-time Grammy award winning horn/string arranger, and former section leader/arranger of Prince and the New Power Generation.

Philip Lassiter is an 11-time Grammy award winning horn/string arranger, and former section leader/arranger of Prince and the New Power Generation.

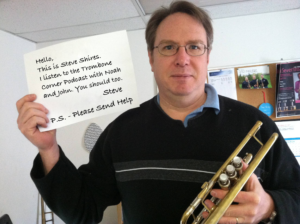

Steve Shires is best known in the brass world as the founder of the S. E. Shires Company, crafter of custom trombones and trumpets. His passion for designing and building brass instruments grew from his love of playing the trombone. Steve received his undergraduate degree in trombone performance from the University of Iowa, where he studied with John Hill and George Krem. A true trombonist, he skipped theory class to apprentice as a brass repair technician at West Music Company in Iowa City and was soon developing his craft by converting old small bore tenor trombones into alto trombones. While continuing his trombone studies in Chicago with legendary Chicago symphony brass section members Arnold Jacobs, Edward Kleinhammer, Frank Crisafulli, and Jay Friedman, he worked for the Schilke Music Company, learning the art of spinning brass instrument bells, as he absorbed the high standards of quality that Schilke represents. In 1986, Steve and his wife Cathy relocated to Boston. It was there that he gained much of his knowledge of the Horn, working for Osmun Brass Instruments, the nationally respected shop for horn repairs and restorations. It was here that Steve gained the invaluable experience of rebuilding valves, cutting bells, and restoring Geyer, Kruspe, Conn, and Paxman horns.

Steve Shires is best known in the brass world as the founder of the S. E. Shires Company, crafter of custom trombones and trumpets. His passion for designing and building brass instruments grew from his love of playing the trombone. Steve received his undergraduate degree in trombone performance from the University of Iowa, where he studied with John Hill and George Krem. A true trombonist, he skipped theory class to apprentice as a brass repair technician at West Music Company in Iowa City and was soon developing his craft by converting old small bore tenor trombones into alto trombones. While continuing his trombone studies in Chicago with legendary Chicago symphony brass section members Arnold Jacobs, Edward Kleinhammer, Frank Crisafulli, and Jay Friedman, he worked for the Schilke Music Company, learning the art of spinning brass instrument bells, as he absorbed the high standards of quality that Schilke represents. In 1986, Steve and his wife Cathy relocated to Boston. It was there that he gained much of his knowledge of the Horn, working for Osmun Brass Instruments, the nationally respected shop for horn repairs and restorations. It was here that Steve gained the invaluable experience of rebuilding valves, cutting bells, and restoring Geyer, Kruspe, Conn, and Paxman horns.

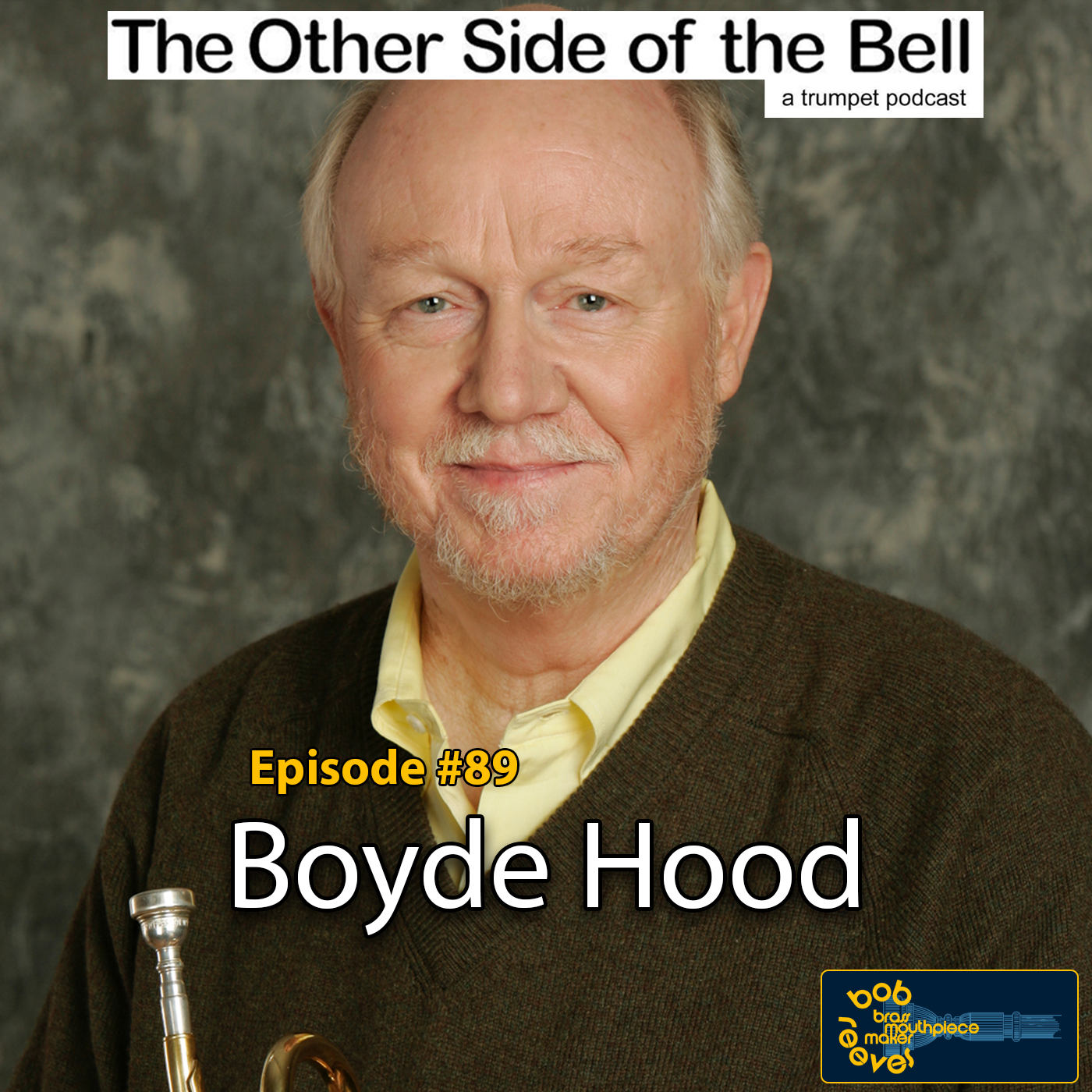

A native of Dallas, Texas, Philharmonic trumpeter Boyde Hood received his BM degree in trumpet performance from the Eastman School of Music and master of music degree in theory and composition from Ball State University. He is a member of the Los Angeles Philharmonic and performs regularly with the Philharmonic’s New Music Group and the Philharmonic Brass Trio. Mr. Hood has played principal trumpet with the Los Angeles Chamber Orchestra, Royal Ballet and American Ballet Theater and has recorded extensively for major motion picture and television studios. He has been a member of the Dallas and Milwaukee Symphonies, assistant principal of the Rochester Philharmonic, and first trumpet with the Marlboro Festival Orchestra.

A native of Dallas, Texas, Philharmonic trumpeter Boyde Hood received his BM degree in trumpet performance from the Eastman School of Music and master of music degree in theory and composition from Ball State University. He is a member of the Los Angeles Philharmonic and performs regularly with the Philharmonic’s New Music Group and the Philharmonic Brass Trio. Mr. Hood has played principal trumpet with the Los Angeles Chamber Orchestra, Royal Ballet and American Ballet Theater and has recorded extensively for major motion picture and television studios. He has been a member of the Dallas and Milwaukee Symphonies, assistant principal of the Rochester Philharmonic, and first trumpet with the Marlboro Festival Orchestra. Since his retirement from the LA Philharmonic and USC, Boyde taught at the Eastman School of Music for one Semester, has resumed his compositional activities, and continues to teach privately from his home and on Zoom.

Since his retirement from the LA Philharmonic and USC, Boyde taught at the Eastman School of Music for one Semester, has resumed his compositional activities, and continues to teach privately from his home and on Zoom.

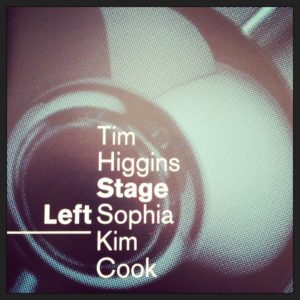

Timothy Higgins was appointed to the position of Principal Trombone of the San Francisco Symphony by Michael Tilson Thomas in 2008. He was previously the acting Second Trombonist with the National Symphony Orchestra in Washington, DC. Mr. Higgins, a Houston native, has a Bachelor’s degree in Music Performance from Northwestern University and has performed with the Chicago Symphony, New York Philharmonic, Milwaukee Symphony, Virginia Symphony, Civic Orchestra of Chicago, Music of the Baroque, Aspen Music Festival, Grand Teton Music Festival, Sun Valley Summer Symphony, Washington National Opera, and Baltimore Symphony. His principal teachers have been Michael Mulcahy (Chicago Symphony), Michael Warny (Houston Grand Opera), and Royce Landon (Des Moines, Iowa). He has participated in music festivals with the Roundtop Music Festival, the National Repertory Orchestra, and the Tanglewood Music Center.

Timothy Higgins was appointed to the position of Principal Trombone of the San Francisco Symphony by Michael Tilson Thomas in 2008. He was previously the acting Second Trombonist with the National Symphony Orchestra in Washington, DC. Mr. Higgins, a Houston native, has a Bachelor’s degree in Music Performance from Northwestern University and has performed with the Chicago Symphony, New York Philharmonic, Milwaukee Symphony, Virginia Symphony, Civic Orchestra of Chicago, Music of the Baroque, Aspen Music Festival, Grand Teton Music Festival, Sun Valley Summer Symphony, Washington National Opera, and Baltimore Symphony. His principal teachers have been Michael Mulcahy (Chicago Symphony), Michael Warny (Houston Grand Opera), and Royce Landon (Des Moines, Iowa). He has participated in music festivals with the Roundtop Music Festival, the National Repertory Orchestra, and the Tanglewood Music Center. Along with a busy orchestra career, Timothy Higgins is a sought after arranger of music. He was the sole arranger of the National Brass Ensemble’s Gabrieli recording. Additionally, he has arranged music for CT3 Trombone Quartet, National Brass Quintet, Bay Brass, and the San Francisco Conservatory of Music Brass Ensemble. Timothy Higgins has also composed works for brass instruments in solo and chamber settings. His arrangements and compositions have been performed by the Washington Symphonic Brass, the Bay Brass, the San Francisco Symphony brass section, the Chicago Symphony brass section, the Los Angeles Philharmonic brass section, and numerous university brass ensembles. His arrangements and original compositions are available through his publishing company, 415Music.

Along with a busy orchestra career, Timothy Higgins is a sought after arranger of music. He was the sole arranger of the National Brass Ensemble’s Gabrieli recording. Additionally, he has arranged music for CT3 Trombone Quartet, National Brass Quintet, Bay Brass, and the San Francisco Conservatory of Music Brass Ensemble. Timothy Higgins has also composed works for brass instruments in solo and chamber settings. His arrangements and compositions have been performed by the Washington Symphonic Brass, the Bay Brass, the San Francisco Symphony brass section, the Chicago Symphony brass section, the Los Angeles Philharmonic brass section, and numerous university brass ensembles. His arrangements and original compositions are available through his publishing company, 415Music. In 2005, Timothy won the Robert Marsteller Solo trombone competition, as well as the ITA Trombone Quartet competition with CT3. While attending the Tanglewood Music Center, Mr. Higgins was awarded the Grace B. Upton Award for Outstanding Fellow. In 2013, Timothy released his solo CD, Stage Left.

In 2005, Timothy won the Robert Marsteller Solo trombone competition, as well as the ITA Trombone Quartet competition with CT3. While attending the Tanglewood Music Center, Mr. Higgins was awarded the Grace B. Upton Award for Outstanding Fellow. In 2013, Timothy released his solo CD, Stage Left.

James Morrison is, by anybody’s standard, a virtuoso in the true sense of the word. Besides the trumpet, this multi-instrumentalist also plays piano, all the brass, saxophones, and double bass.

James Morrison is, by anybody’s standard, a virtuoso in the true sense of the word. Besides the trumpet, this multi-instrumentalist also plays piano, all the brass, saxophones, and double bass. James has been appointed a member of The Order of Australia, he is a Doctor of the University at Queensland Conservatorium of Music and has received a Doctor of Music from the Edith Cowan University Western Australia and the University of Adelaide. He is an Adjunct Professor at the University of South Australia and Vice-Chancellor’s Professorial Fellow. In 2015 James founded his own academy of music in Mount Gambier, South Australia. The James Morrison Academy of Music @ UniSA is an innovative school dedicated to teaching jazz and offering both a Bachelor Degree and post graduate programs. This exciting initiative involves educators from all over the world, transforming young musicians’ lives with inspiration and a love of jazz. In 2017, the JMA partnered with The Juilliard School in New York City to offer an exclusive Honours Program.

James has been appointed a member of The Order of Australia, he is a Doctor of the University at Queensland Conservatorium of Music and has received a Doctor of Music from the Edith Cowan University Western Australia and the University of Adelaide. He is an Adjunct Professor at the University of South Australia and Vice-Chancellor’s Professorial Fellow. In 2015 James founded his own academy of music in Mount Gambier, South Australia. The James Morrison Academy of Music @ UniSA is an innovative school dedicated to teaching jazz and offering both a Bachelor Degree and post graduate programs. This exciting initiative involves educators from all over the world, transforming young musicians’ lives with inspiration and a love of jazz. In 2017, the JMA partnered with The Juilliard School in New York City to offer an exclusive Honours Program. Highlights of 2016 included a recording at Abbey Road Studios with the BBC Concert Orchestra for international release, sold out performances at the Prague Proms, Berlin Philhamonie, Budapest Music Centre and the Lionel Hampton Club in Paris, two sell-out return performances at Ronnie Scott’s Jazz Club in London, two Australian tours, two European tours, a season with the Sydney Symphony Orchestra, a hugely successful solo tour all over the USA including the Miami Beach Jazz Festival, the Newport Beach Jazz Party, performances with John Clayton, Jeff Hamilton and the One O’Clock Lab Band and, of course, International Jazz Day at the White House with the President of the United States.

Highlights of 2016 included a recording at Abbey Road Studios with the BBC Concert Orchestra for international release, sold out performances at the Prague Proms, Berlin Philhamonie, Budapest Music Centre and the Lionel Hampton Club in Paris, two sell-out return performances at Ronnie Scott’s Jazz Club in London, two Australian tours, two European tours, a season with the Sydney Symphony Orchestra, a hugely successful solo tour all over the USA including the Miami Beach Jazz Festival, the Newport Beach Jazz Party, performances with John Clayton, Jeff Hamilton and the One O’Clock Lab Band and, of course, International Jazz Day at the White House with the President of the United States.

Besides everything trumpet Steve”s passions are marathon open water (OCEAN) swimming, and the daunting task of traing his dog Dingoe. He currently resides in San Diego, California, USA, with his wife and two children where he manages

Besides everything trumpet Steve”s passions are marathon open water (OCEAN) swimming, and the daunting task of traing his dog Dingoe. He currently resides in San Diego, California, USA, with his wife and two children where he manages

Born in Lancashire, England and raised in Perth, Western Australia, Adrian Kelly began playing trumpet at the age of six. He has gone on to build an international career as a multi-faceted musician; performing, recording, and writing pop, classical, and jazz music. Adrian is currently engaged in PhD research at Edith Cowan University (Perth, Western Australia). He has served on the board of the Australian Trumpet Guild since 2019, and on the board of JazzWA since 2018.

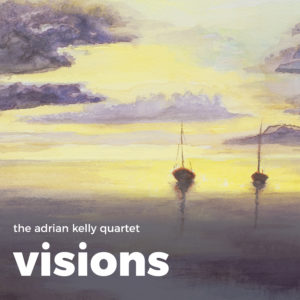

Born in Lancashire, England and raised in Perth, Western Australia, Adrian Kelly began playing trumpet at the age of six. He has gone on to build an international career as a multi-faceted musician; performing, recording, and writing pop, classical, and jazz music. Adrian is currently engaged in PhD research at Edith Cowan University (Perth, Western Australia). He has served on the board of the Australian Trumpet Guild since 2019, and on the board of JazzWA since 2018. 2020 sees the release of two releases: Visions a suite of pieces for improvising quartet written to accompany the visual art of Robert John Kelly (Adrian’s father), and Cry, “Wolf!” an album of music featuring an artificial intelligence ‘improviser’ along with an electric jazz quartet. All of Adrian’s music is available through iTunes and other digital platforms, and through links provided on his website.

2020 sees the release of two releases: Visions a suite of pieces for improvising quartet written to accompany the visual art of Robert John Kelly (Adrian’s father), and Cry, “Wolf!” an album of music featuring an artificial intelligence ‘improviser’ along with an electric jazz quartet. All of Adrian’s music is available through iTunes and other digital platforms, and through links provided on his website. Adrian has delivered classes in jazz music and trumpet at Edith Cowan University, The University of Western Australia (Australia), and the Hong Kong Institute of Education (China). He has presented masterclasses to students at Lasalle College (Singapore), the Hong Kong Institute of Education, ShangHai Conservatory of Music, XingHai University, and Harbin Teacher Training College (China), and at independent venues in

Adrian has delivered classes in jazz music and trumpet at Edith Cowan University, The University of Western Australia (Australia), and the Hong Kong Institute of Education (China). He has presented masterclasses to students at Lasalle College (Singapore), the Hong Kong Institute of Education, ShangHai Conservatory of Music, XingHai University, and Harbin Teacher Training College (China), and at independent venues in